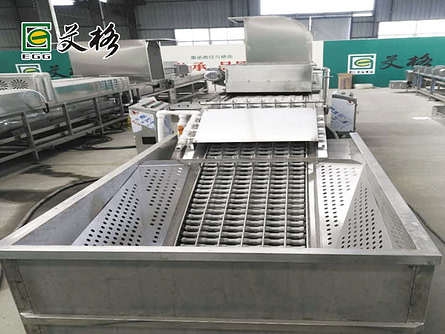

Industrial Egg Peeling Machine, Hard Boiled Egg Peeling Machine, Egg Shelling Machine

Our industrial Egg Peeling Machine can be used by some small egg production factories without need of egg peeling production line. With our latest egg peeling machine, users are able to increase daily egg output. Of course, the egg peeling machine can be used for peeling hard-boiled egg, soft boiled egg as per users’ practical demand. Our High-capacity egg peeler Can effectively grow your factory productivity. Egg Automation Technology Ltd has been focused on the design of various egg peeling based on different egg processing needs in the industry for more than ten years. We are here to provide you with the best egg processing machines with capacity from 4000 eggs/hour up to 30000 eggs/hour to help you achieve better production efficiency.

Egg Peeling Machine Capacity of 5000& 8000 eggs/hour

The following are types of egg peeling machines that save labor cost largely. Our egg machine is featured by low fault rates and very little maintenance.

Full Process of industrial egg peeling and boiling

Full Process we can separate In a 12 part the process will start from Automatic Egg Feeding and will end at vacuum packaging. This full process will never take more then 2 hours if you use our High productive egg peeling machine let’s explain one by one

1. Automatic Egg Feeding

Automatic Egg Feeding machines have revolutionized the process of feeding eggs in various settings, such as poultry farms and food production lines. These machines provide a more efficient, hygienic, and controlled method of delivering eggs to the desired recipients or destinations.

Process

The Automatic Egg Feeding process using a machine involves several steps:

Egg Collection: The eggs are collected from the source, such as a poultry farm or an egg production facility. They are placed onto trays or conveyor belts, ready to be fed into the machine.

Sorting and Grading: The machine is equipped with sensors and cameras that detect the size, shape, and quality of the eggs. The eggs are then sorted and graded based on the predefined parameters. This ensures that only high-quality eggs are fed through the machine.

Cleaning and Sanitizing: Before being fed into the machine, the eggs are cleaned and sanitized to remove any dirt, dust, or contaminants. This step is crucial to maintain hygiene and food safety standards.

Feeding Mechanism: The Automatic Egg Feeding machine has a specially designed feeding mechanism, which gently picks up the eggs and transfers them to the next stage of the process. This mechanism could include vacuum suction cups, robotic arms, or conveyor belts with carefully calibrated speed settings to minimize the risk of breakage or damage.

Packaging or Cooking: Depending on the intended use of the eggs, the machine can either package the eggs for transportation and sale or directly cook them in various ways, such as boiling, frying, or scrambling. In both cases, the machine ensures that the process is done efficiently and consistently.

Quality Control: Throughout the entire process, the machine continuously monitors the quality of the eggs and the final product, whether it is packaged eggs or cooked eggs. Any deviations from the set standards are automatically flagged, and the affected eggs are removed from the process.

Waste Management: The Automatic Egg Feeding machine is designed to minimize waste by handling the eggs carefully and ensuring optimal use of resources. Any broken or damaged eggs are separated and directed to a waste disposal system.

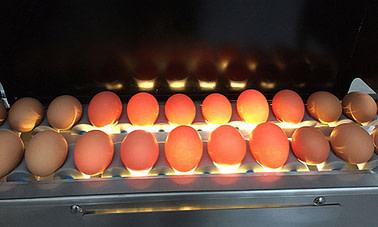

2.Light Transmission Detection in Egg Peeling

Light transmission detection has found a unique application in the world of egg peeling, allowing for a more efficient and accurate assessment of the egg's readiness for peeling. The process uses the principles of light transmission to evaluate the degree of boiling and the ease with which the shell can be removed.

Preparing the Eggs: First, the eggs are boiled to the desired level, whether soft, medium, or hard. Once they have reached the preferred boiling point, they are cooled in cold water or an ice bath to halt the cooking process and make handling easier.

Light Source: A suitable light source, such as an LED or a small flashlight, is required for the light transmission detection process. This light source will shine through the egg, enabling the assessment of its boiling degree and peeling readiness.

Positioning the Egg: The boiled egg is placed between the light source and a sensor or a detector. In a darkened environment, the egg is held against the light, and the light transmission is observed. Alternatively, a specialized device can be designed to hold the egg in place and focus the light on the egg.

Observing Light Transmission: As the light passes through the egg, the observer or sensor can detect variations in light transmission. An egg that is ready for peeling will display specific patterns or levels of light transmission. The difference in light transmission is caused by the varying thickness of the eggshell, the egg white, and the egg yolk.

Interpreting Results: By analyzing the patterns and intensity of light transmission, an informed decision can be made about the readiness of the egg for peeling. This method helps to ensure that the egg has been cooked to the desired level and that the shell can be removed without damaging the egg white or yolk.

Peeling the Egg: Once the light transmission detection process confirms that the egg is ready for peeling, the shell can be carefully removed using traditional methods, such as tapping, rolling, or using a peeling device.

3. Egg Brush Cleaning

Egg brush cleaning is an essential process in maintaining hygiene and cleanliness of eggs before they are packaged, sold, or used in various culinary applications. This Is One of the important process of industrial egg peeling. The process involves gently brushing the surface of the eggs to remove dirt, debris, and potential contaminants, ensuring that the eggs are safe for consumption.

Process:

Preparing the Eggs: The first step in egg brush cleaning is to collect the eggs from their source, such as a poultry farm or an egg production facility. Eggs are then placed on trays or conveyor belts, ready for the cleaning process.

Selecting the Right Brush: Choose a soft-bristled brush specifically designed for egg cleaning. These brushes are gentle on the eggshells, minimizing the risk of damage or breakage. Brushes can be manual or integrated into an automatic egg cleaning machine.

Wetting the Brush (Optional): Depending on the level of dirt on the eggs, it may be helpful to slightly wet the brush before cleaning. This can help to loosen any stubborn debris or dried-on dirt. However, be cautious not to soak the brush, as excessive moisture may weaken the eggshell or promote bacterial growth.

Cleaning the Egg: Hold the egg firmly but gently in one hand, being careful not to apply too much pressure. With the other hand, use the brush to gently scrub the surface of the egg, paying attention to any areas with visible dirt or debris. If using an automatic egg cleaning machine, the machine will take care of this step by passing the eggs through rotating brushes or soft sponge rollers.

Rinsing the Egg (Optional): After brushing the egg, a gentle rinse with clean water can help to remove any residual dirt or debris. Ensure that the water temperature is not too cold or too hot, as extreme temperatures can cause the eggshell to crack or promote bacterial growth. If using an automatic egg cleaning machine, the machine may have an integrated rinsing system.

Drying the Egg: Once the egg has been cleaned and rinsed (if applicable), it is crucial to dry the egg thoroughly to prevent bacterial growth. This can be done using a soft, lint-free cloth or by placing the egg on a drying rack with ample air circulation. Automatic egg cleaning machines may have built-in drying systems, such as air blowers or heated drying chambers.

Inspection and Packaging: After the egg brush cleaning process is complete, a final inspection is performed to ensure that the eggs are clean and free of any visible dirt or debris. The eggs are then ready for packaging, transportation, and sale or to be used in various culinary applications.

4. Precooking Process with Industrial Egg Peeling Machine

The precooking process is a crucial stage in preparing eggs for various culinary applications, especially when utilizing an industrial egg peeling machine. This process ensures that the eggs are cooked to the desired level, making them ready for efficient peeling and further processing

Process:

Precooking: Place the eggs in a large pot or an industrial egg boiler and cover them with water. Heat the water until it reaches a gentle boil, then adjust the cooking time based on the desired doneness (soft, medium, or hard-boiled).

Cooling: Once the eggs are cooked, transfer them to an ice bath or cold water to halt the cooking process and cool the eggs down, making them easier to handle.

5. Egg Boiling Process for Industrial Egg Peeling Machine

The precooking process is a crucial stage in preparing eggs for various culinary applications, especially when utilizing an industrial egg peeling machine. This process ensures that the eggs are cooked to the desired level, making them ready for efficient peeling and further processing

Process:

Adjusting Cooking Time: Determine the desired doneness for the eggs (soft, medium, or hard-boiled) and set the appropriate cooking time accordingly.

Monitoring the Boiling Process: Keep an eye on the boiling process to ensure even cooking and prevent overcooking or undercooking the eggs.

Cooling the Eggs: Once the eggs have reached the desired level of boiling, immediately transfer them to an ice bath or cold water to halt the cooking process and make them easier to handle.

Preparing for Peeling: Drain the water and dry the eggs before loading them into the industrial egg peeling machine.

6. Egg Cooling

- After boiling the eggs, carefully remove them from the boiling water using a slotted spoon.

- Prepare a large bowl filled with cold water and ice cubes.

- Transfer the boiled eggs into the bowl of ice water, ensuring that they are completely submerged.

- Let the eggs cool in the ice water for at least 10 minutes or until they are fully cooled down.

- Once the eggs are cooled, they can be peeled or refrigerated for later use.

For industrial purposes, the cooling and peeling process may involve specialized equipment such as an industrial egg peeling machine, which can quickly cool and peel large quantities of eggs. However, the basic process for cooling eggs remains the same.

7. Step-by-step process for egg shelling of egg peeling industrial

=> Tap the egg gently on a hard surface to create a small crack. - Use your fingertips or the back of a spoon to tap the egg gently on a hard surface to create a small crack in the shell.

=> Roll the egg gently between your palms to loosen the shell. - Place the egg in the palm of your hand and gently roll it back and forth between your palms to loosen the shell.

=> Hold the egg under running water to help loosen the shell. - Hold the egg under running water and allow the water to flow over the egg as you gently rub the shell with your fingers to help loosen it.

=> Peel away the shell starting from the larger end of the egg where the air pocket is located. - Gently peel away the shell starting from the larger end of the egg where the air pocket is located, using your fingertips to help remove the shell.

=> Gently remove the shell in small pieces, being careful not to remove any of the egg white or yolk. - Carefully remove the shell in small pieces, taking care not to remove any of the egg white or yolk.

=> Rinse the egg under running water to remove any small shell pieces. - Rinse the egg under running water to remove any small shell pieces that may be stuck to the egg.

=> Pat the egg dry with a clean paper towel. - Use a clean paper towel to pat the egg dry after it has been peeled.

Industrial Egg peeling Machine Features

1.Higher Efficiency

Zhucheng Egg Automation Technology Co.,Ltd, model AG-M3 and AG-M4 egg grader can load 30 eggs at a time by using a vacuum egg lifter, the AG-E1 and AG-E2 egg grader can connect with the rod conveyor from chicken shed directly, the eggs will flow to the egg grader smoothly.

2.Candling Device

All egg graders use 6 rows of LED light to perform candling inspection for detecting any leaks, dirt, and cracks. Candling cabinet and mirrors are also equipped for a better inspection result.

3.PLC Control System

Zhucheng Egg Automation Technology Co.,Ltd, AG-E1, AG-E2, AG-E3 and AG-E4 type egg graders are all equipped with touch screen PLC control system. Core features are as follows:

① Changing grading setting is easy and simple, weighing precision correction;

② Sum up total capacity per shift and per grade;

③ Malfunction alarm and display;

④ Self-diagnosis system.

As a responsible overseas-oriented egg machine manufacturer in China, we are supported with top-tiered technical team and after-sale team. From raw material to machine processing technology, a brand new egg machine must be going through all strict quality test before shipping out of our factory to make sure all kinds of egg processing equipments are anti-corrosive, non-deformation, long lifespan and extremely low fault rate during your daily egg production. We specialize in various egg processing machines including egg peeling machine, quail egg peeling machine, egg grading machine, egg washing machine, egg printer, egg separator, egg farm packer, hard boiled egg production line, soft-boiled egg production line etc. Zhucheng Egg Automation Technology Co.,Ltd is committed to provide overseas customers with satisfied quality of various egg processing machines and best comprehensive egg production line solution.